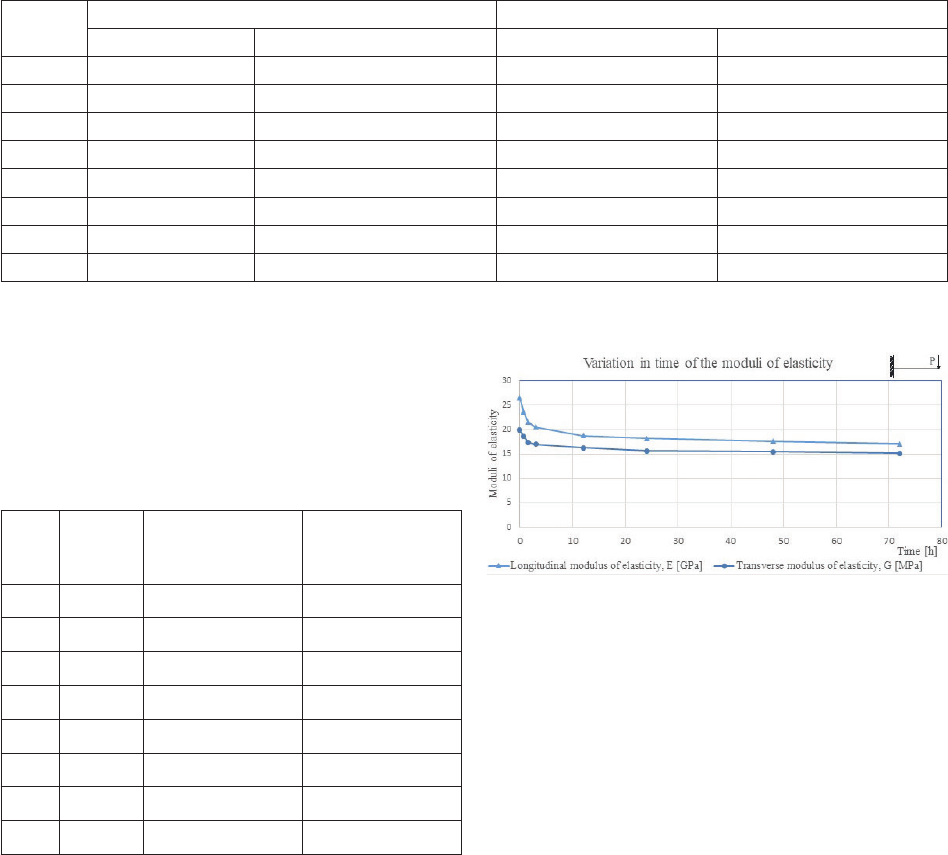

On the variability in time of the longitudinal modulus of elasticity E and the traverse modulus of elasticity G 117

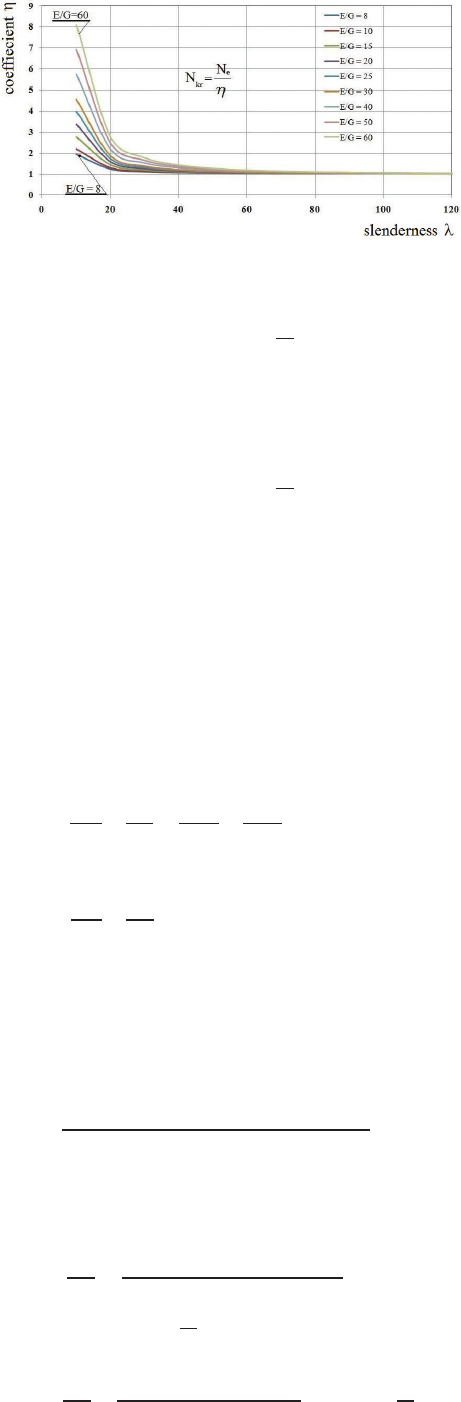

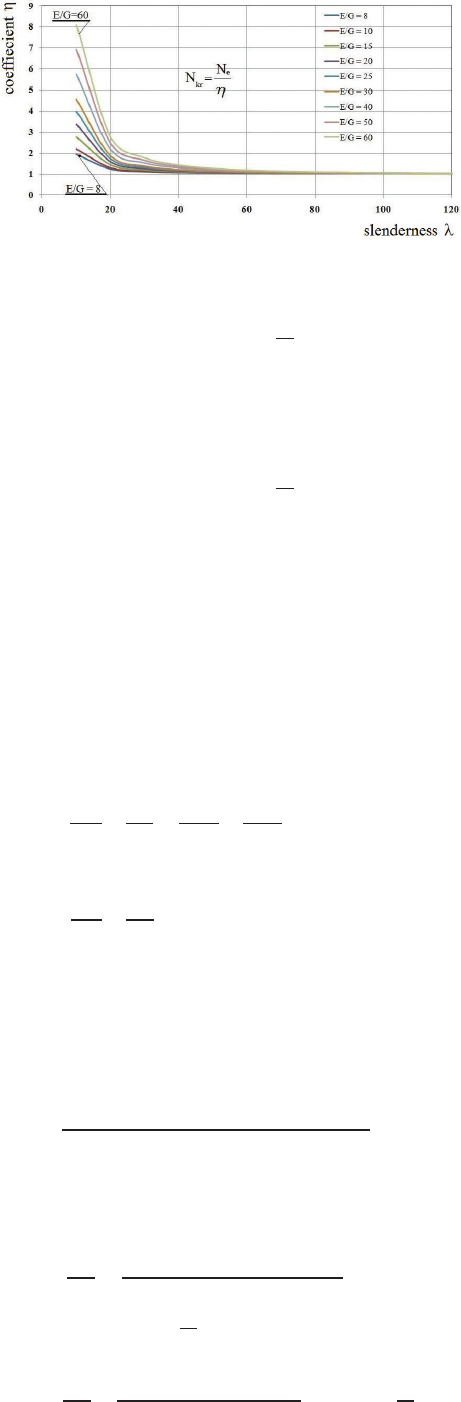

Kowal presents how grows the coecient decreasing the

load capacity η for bars of a slimness of λ < 20 (Fig. 2).

The coecient η is important since it tells us, how many

times the critical load-bearing capacity of a constricted bar

decreases depending on the slimness λ and on the relation

E/G according to the equation by Kowal.

Since wood is a natural brous composite, similar phe-

nomena should be expected as in articial brous com

pos-

ites. For these reasons the author of the paper has been deal-

ing, for many years, with the exploration of wood as a b

rous

composite, including the moduli of elasticity of wood.

In the referenced literature of this subject matter no re-

search by other authors has been noticed about a change in

time of the moduli of elasticity E and G of wood, as well as

on the critical load-bearing capacity of wooden structures

as well as the variations of their rigidity in time.

Considering the impact of wood (as reected by the mag

nitudes of E and G) on the aesthetics, durability and safety

of the facilities made of wood, the author of the paper con-

ducted her own experiment in order to show how changes

the value of the moduli of elasticity of wood in time. The

information on the moduli of elasticity, both longitudinal E

and transverse ones G, has the basic meaning for the devel-

opment of the large-spatial facilities made of glued wood,

the assessment of the rigidity and the load-bearing capacity

in time. The knowledge of the magnitudes of E and G pro-

vides a possibility to forecast in time the variations of an ar-

chitectonic form and the load-bearing capacity of a structure.

The objective of the research

The objective of the research conducted by the author of

this paper is to show that:

1. The tendency of the variations of the moduli of trans-

verse rigidity G and that of longitudinal elasticity E can be

diagnosed on the basis of the measurements of deections.

2. The rigidity of a wooden element changes in time.

Description of own research

Theoretical basics of the method

The author of the paper has dealt for many years with

the theoretical basics of the research about the moduli of

longitudinal elasticity and that of transverse elasticity. In

her publication dated 2020 (Misztal 2020), she specied

the algorithm to determine the values of longitudinal elas-

ticity E and that of transverse elasticity G, as well as she

examined the model of a spruce wood beam. Reminded in

this paper is the course of calculations of the moduli E and

G, in order to prove that the rigidity of a wooden element

varies in time. To this aim, the author of the paper conduct-

ed an experiment on two models of a cantilever beam made

of pine wood.

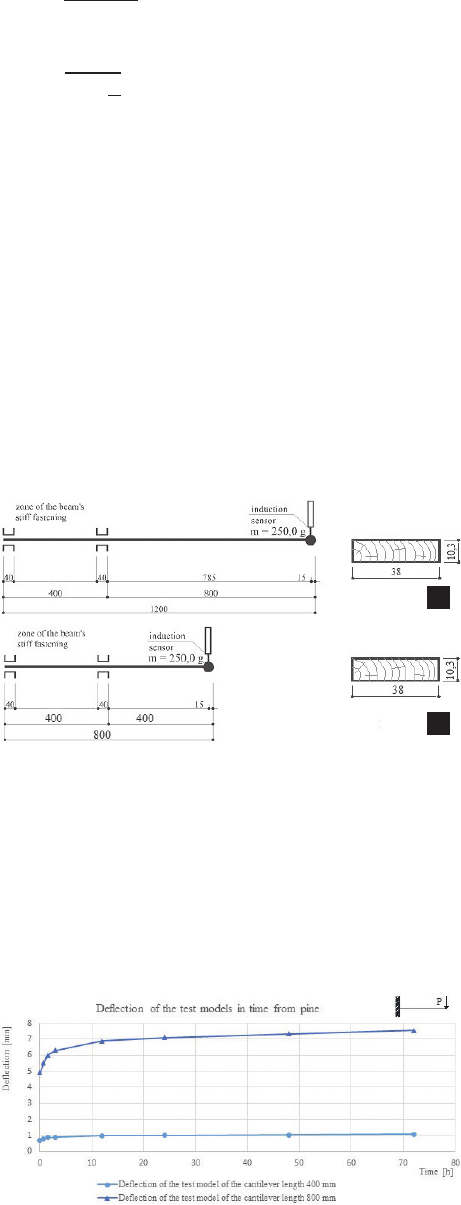

In the research scheme adopted for the research the

total deection of the supporting beam depends on the

bending rigidity EJ and on the shape rigidity FG of the bar

(E – modulus of longitudinal elasticity, G – modulus of

transverse elasticity, J – moment of inertia of the bar sec-

tion, F – cross-sectional area of the bar).

An experiment lasting for 72 hours was scheduled. The

examination of two cantilever beams having the length of

l

1

= 2l

2

and l

2

was conducted (2). The system of equations

(3) and (4) was arranged:

For the cantilever beam of the lenght l

1

= 800 mm, where

l

1

= 2l

2

(2)

(3)

For the cantilever beam of the lenght l

2

= 400 mm:

(4)

Cantilever beam’s cross-section:

Geometric moment of inertia of the cantilever beam’s

cross-section:

The coecients designated as A were introduced

– equation (5) and B – equation (6) (5)

(6)

Fig. 2. Graph of the reduction factor η for the critical load-bearing

capacity of compressed members according to equation (1)

(elaborated by Misztal 2018)

equation (1):s ssssssssss ss

N

kr

– critical load of the composite member, N

e

– Euler’s critical load,

η – reduction factor for the Euler-based critical load according to

classical mechanics (source: Kowal 1996)

Il. 2. Wykres współczynnika η zmniejszającego nośność krytyczną

prętów ściskanych według wzoru (1) (oprac. Misztal 2018)

wzór (1): cc cc

N

kr

– siła krytyczna pręta kompozytowego,

N

e

– siła krytyczna według Eulera,

η – współczynnik zmniejszający siłę krytyczną liczoną z wzoru Eulera

według zasad mechaniki klasycznej (źródło: Kowal 1996)

1

=

1

3

3

+

1

=

8

2

3

3

+

2

2

= 3.8 × 1.03 × 10

−4

m

2

= 3.914 × 10

−4

m

2

=

3.8 × 10

−2

[

m

]

×

(

1.03 × 10

−2

[

m

]

)

3

12

= 0.3460302 × 10

−8

m

4

=

3.8 × 10

−2

[

m

]

×

(

1.03 × 10

−2

[

m

]

)

3

12

= 0.3460302 × 10

−8

m

4

=

2

3

3

=

2.50×

(

40 × 10

−2

)

3

m

3

3 × 0.3460302 × 10

−8

m

4

= 15412912.9 [

N

m

]

=

2

3

3

=

2.50×

(

40 × 10

−2

)

3

m

3

3 × 0.3460302 × 10

−8

m

4

= 15412912.9 [

N

m

]

=

2

=

2.50× 40 × 10

−2

m

3.914 × 10

−4

m

2

= 2554.9 [

N

m

]