ThesafeguardingoftheValedeMilhaçosGunpowderFactory / ZabezpieczeniefabrykiprochuwValedeMilhaços 23

undertakes the actions necessary to renewing the licences

both for the João Peres boiler and for the Joseph Farcot

steam engine.

The certication and subsequent licence renewal pro-

cedures for this machinery and its activities were duly

identied and constitute essential dimensions to overall

operational conservation for purposes of demonstrating

the functioning of the pressurised equipment.

This process is submitted to the Instituto Português da

Qualidade and correspondingly requesting an inspection.

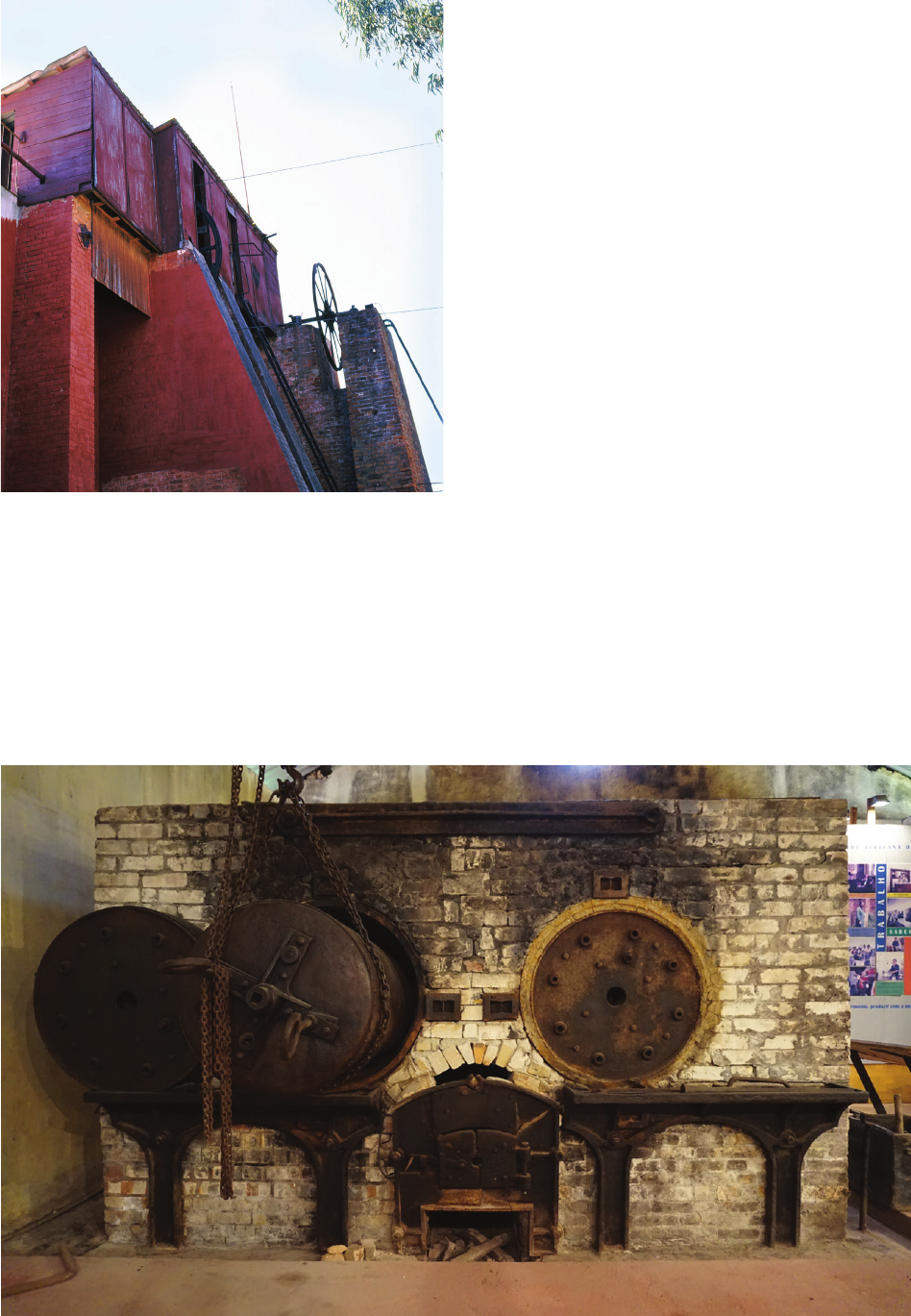

The boiler inspection undertaken by a competent exter-

nal organism (currently the Instituto da Soldadura e Qua-

lidade) includes the testing of the hydraulic pressure and

the verication of the inner cylinder through direct obser-

vation and testing the steam pressure.

In relation to the process of renewing the authorisation

for the boiler to operate, this involves the testing of both

the pressure and the boiler safety valve by an authorised

inspector who, after having conrmed the equipment

meets the requirements, drafts a report that is then submit-

ted to the licensing service.

Having conrmed the good operational conditions of

the steam generator, an inspection was made of the steam

engine and it thus proved possible to obtain the renewal

of its licence, the rst for a museum context in Portugal,

by the same public entity (Instituto Português da Quali-

dade)

5

.

The pressure gauge – the instrument measuring the

build-up of steam – installed and functional in the boiler

belongs to the Wika brand and also receives a certicate

of periodic inspection (issued by the TAP Laboratory)

6

.

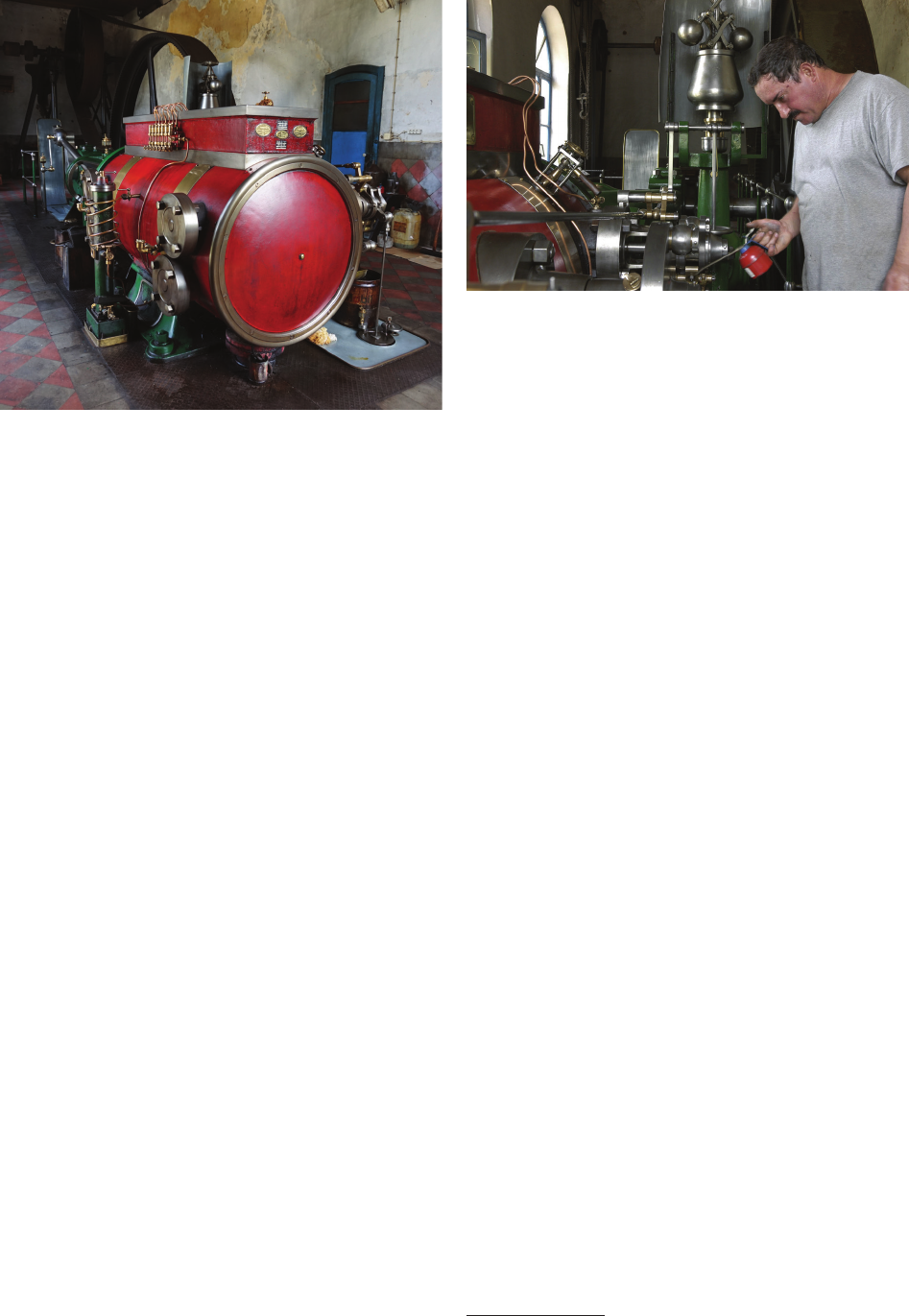

The authorisation for the operating of the Joseph Far-

cot brand steam engine, built in 1900 (thus not attributed

any construction certicate) and with its nominal poten-

tial of 125 cavalos vapor equivalent to around 92 Kw,

falls under the auspices of Decree Law no. 61/2009, of

9 March.

The operating rate for which the João Perez steam

generator is authorised is 5-bar taking into consideration

the demonstration purpose of the motor system in the

Gunpowder Circuit and given that the steam machine is

correspondingly no longer used under a production re-

gime.

Following the same legal practice in eect for indus-

trial plant and equipment, the two operating licences are

axed to the buildings housing the boiler and the machine

and thus fully available for observation by the users and

visitors of the Seixal Municipal Ecomuseum.

5

In 2015 and 2016, with the updating of the legal and administrative

framework stemming from the new Organic Law for the Ministry of the

Economy, enacted in 2014 (Decree Law 11/2014, of 22 January), the

entity responsible for the industrial licensing of pressurised equipment

became the Portuguese Institute of Quality. This was thus the entity that

received the request to renew the boiler licence in 2016 and 2018 and the

steam engine in 2017.

6

The metrological verication conditions and the issuing of certi-

cate for this equipment, required by the licence for steam generation

arises from Decree Law no. 291/90 of 20 September, Decree no.

422/98 of 21 July and Dispatch no 1173/2015 (with the latter valid until

31 December 2017) but which remains applicable.

We would note that periodic pressure testing represents

a potentially destructive operation in keeping with its

design and goal of revealing any defects existing in the

equipment and in itself representing a process of worsen-

ing or creating defects in the boiler. Hence, irrespective of

such testing being a legal requirement for monitoring the

prevailing safety conditions, it should be our objective to

minimise such recourse while simultaneously maintain-

ing all of the conservation procedures and tests that are

non-destructive to the safety conditions.

The inspections undertaken for the Vale de Milhaços

Gunpowder Factory sought to reconcile the operational

conservation with the principle of minimum intervention

out of respect for the historical background of these ob-

jects, especially the alterations they have been subject to

over the course of time whenever such do not constitute

factors of degradation and corrosion and in addition to the

reversibility, stability and compatibility of the materials

applied in relation to those already existing.

Conclusions

While we understand the added value that operational

conservation does also bring to heritage in terms of its

interpretation and mediation, we are nevertheless aware of

the technical and human limitations this presents.

The musealisation project has hitherto been able to

source machine operators from among the former factory

workers, whether through professionally allocating them

to the Seixal Municipal Ecomuseum team or through vol-

untary collaborations. However, we have not yet been

able to train any new operators.

Our experience tells us of the need to always have

a “plan B” available, evaluating the sustainability of the

project for safeguarding and the model for managing the

heritage on the Black Gunpowder Circuit of the Vale de

Milhaços Gunpowder Factory due for implementation

over forthcoming years.

Establishing partnerships with universities and research -

ers can develop new studies on the industrial heritage,

in a multidisciplinary scientic perspective. This is the

case of the current project IH4Future – Material Culture,

ScienticCulture:industrialheritageforthefuture where

researchers from Historical, Museological, Material and

Conservation sciences consider the scientic study of the

Vale de Milhaços Gunpowder Factory, namely the mate-

rial characterisation of an important part of the integrated

heritage using dierent analytical techniques. These stud-

ies will contribute to assessing the conservation state and

to the musealisation process of the Gunpowder Circuit,

with scientic-based knowledge on the industry history

and technological development.

We are aware of the temporal limits on the process that

began with the Gunpowder Circuit and it remains our ob-

jective to ensure an alternative plan for its in situ conser-

vation. We nevertheless know that the technological value

of the Vale de Milhaços heritage is strengthened by its

operational conservation and that any other alternatives

would hold repercussions impacting on the level of recog-

nition attributed by its visitors and beneciaries.