TheTodHeadlighthouselantern / LatarniamorskaTodHead 15

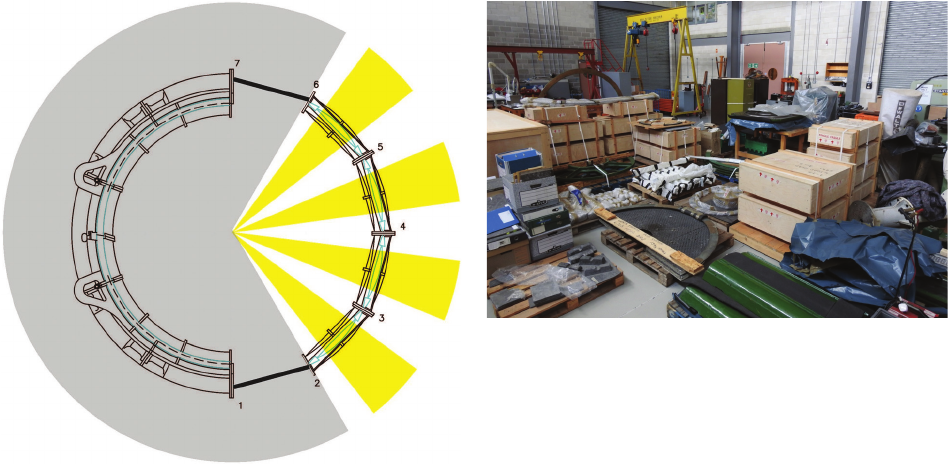

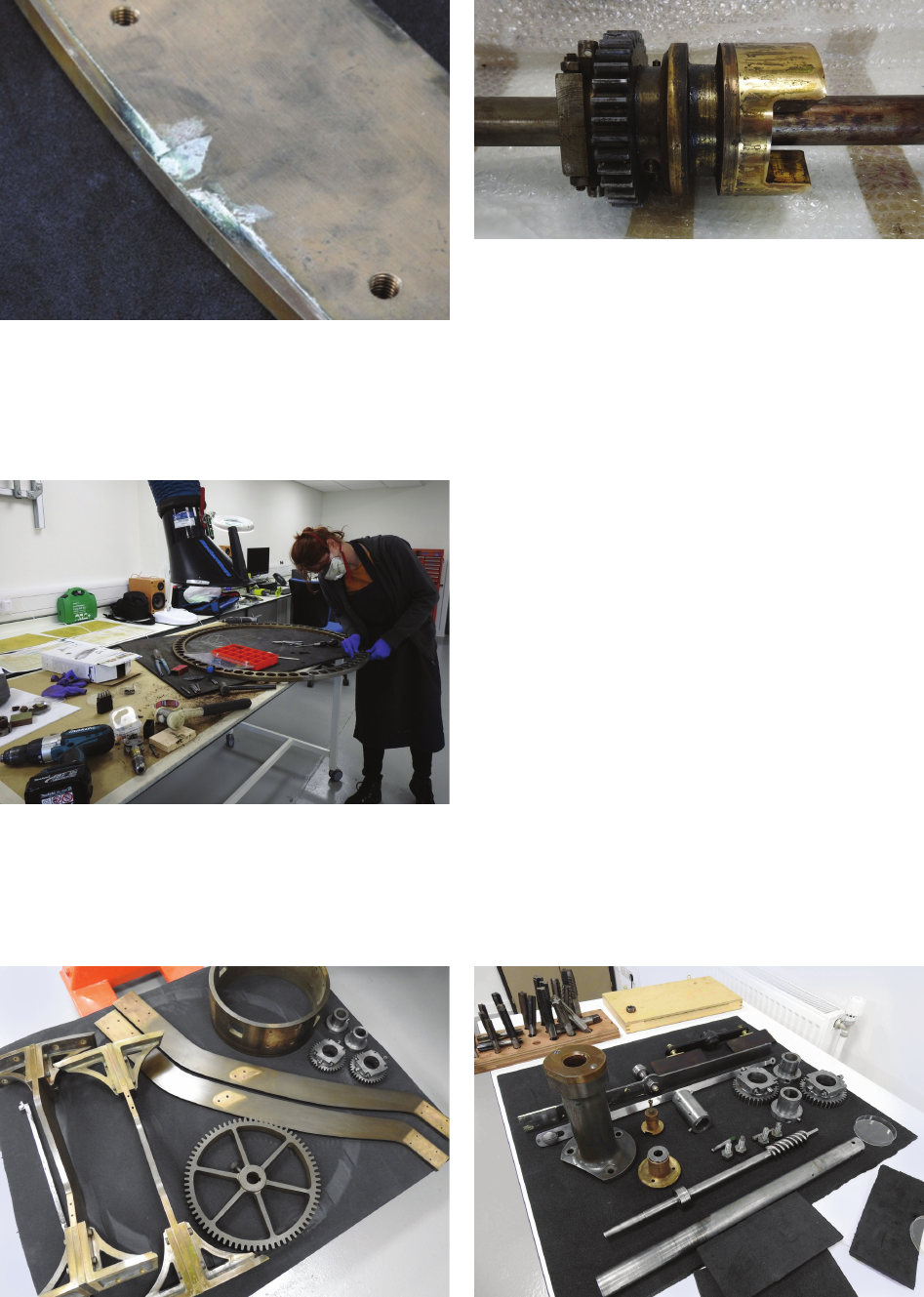

Fig. 15. The lantern being reassembled

(source: image courtesy of National Museums Scotland)

Il. 15. Latarnia ponownie zmontowana

(źródło: zdjęcie dzięki uprzejmości National Museums Scotland)

The cleaning operations also involved cleaning 35 kilos

of screws. We were dealing with an object dating from the

end of the 19

th

century which had been modied through-

out the 20

th

century. The dierences in the standardization

systems of the dierent elements testify to this: the ori

ginal elements are in British Standard Whitworth, the ball

bearing is in United National Fine, some elements on the

platform are in metric and the lens screws do not belong

to any known system.

The two lens panels dismantled in 1977 were separat-

ed from the rest of the lantern. Thanks to the collaboration

of the Northern Lighthouse Board, we were able to nd

their location in the reserves of the Lighthouse Museum in

Fraser burgh, a town in the Grampian Mountains, north of

Aberdeen. Thanks to their collaboration, we were able to

recover these panels. Nevertheless, of the 18 lens panels,

one is missing. It is the bull eye (middle part) numbered 1/2.

After cleaning the parts (Figs. 13, 14), reassembly began.

Once the mechanism was completed, the machine case

was closed and the mechanical roller bearing installed.

The object then weighed nearly two tonnes. Before being

completed, the mechanism had to be moved to its nal

location because the capacity of the lifting tools did not

exceed two tonnes.

For safety reasons, the mechanism was xed to the

ground with 15 cm long dowels. It is important to note that

not everything above the ball bearing was xed since it

must be free to rotate. Therefore, the three tonnes of lenses

were simply placed on the ball bearing.

The wheel that transmits the movement of the mecha-

nism to the lenses was the rst element to be added. Next

came the central pillar, as well as the white paint ed arms

supporting the inner platform (xed) and the green paint-

ed arms supporting the lenses (rotating) (Fig. 15). Final-

ly, the “bottom”, which is the rst level of lenses, was

raised; then the structural elements to support the mirrors.

This is how the lighthouse looked in the storage area

of the National Museums Scotland (National Museums

Collection Centre) at the 1

st

of September 2019.

Conclusion

Before continuing this work, the team must face two is-

sues. The rst is that while all the lens panels have been

found, this is not the case for all the screw elements that

supported them. About 60% of the lens screws are missing.

In addition, these are screws that do not belong to a stand-

References /Bibliografia

[1] Lighthouse of Alexandria, [in:] Encyclopaedia Britannica, https://

www.britannica.com/topic/lighthouse-of-Alexandria, [n.d.], [ac-

cessed: 26.11.2019].

[2] Figuier L., LesMerveilles de laScience ou Descriptionpopulaire

des Inventions humaines, T. 4, Furne, Jouvet et Cie, Paris 1870,

419–470.

[3] Fresnel A., Mémoiresurunnouveausystèmed’éclairagedesphares

luàl’AcadémiedesSciencesle29juillet1822, © Ecole nationale

des Ponts et Chaussées, 1822.

[4] Brewster D., On the Construction of Polygonal Lenses, and their

Combination with Plain Mirrors, for thepurposes of Illumination

in Lighthouses, Transactions of the Royal Society of Edinburgh,

Vol. 11, Edinburgh, published by Charles Tait, Bell and Bradpute

and T. Cadell, London 1831, 53.

[5] Morrison-Low A.D., NorthernLights, National Museums Scotland

and the Royal Scottish Society of Arts, Edinburgh 2010, 239.

[6] Beillard A., Recherches sur l’horlogerie: ses inventions et ses

célébrités:noticehistoriqueetbiographique,d’aprèslesdiversdoc-

umentsdelacollectiondel’écoled’horlogeried’Anet, E. Bernard,

1895, 168.

ardized threading system. They must therefore be manufac-

tured by an external company specically for this project.

The second thing that will allow the site to resume will

be the installation of a scaolding for the second and third

lens levels.